Connection method of hydraulic cylinder and pump station

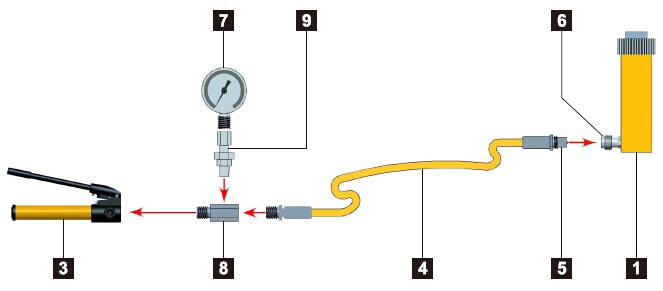

Single-acting push application,such as in a press

The hand pump offers controlled cylinder advance, but may require many hand pump strokes in longer stroke applications when the cylinder capacity is 25 ton or above.

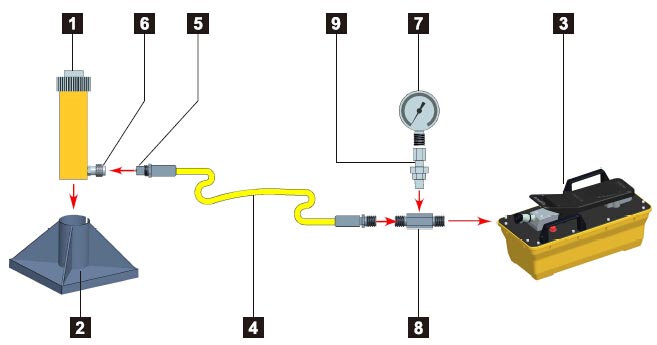

Single-acting cylinder with longer stroke used for lifting applications

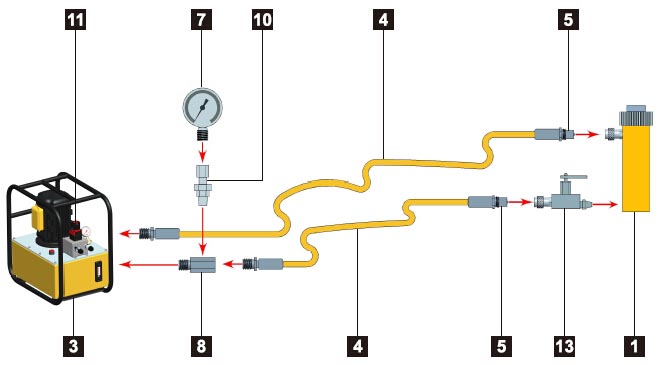

Double-acting cylinder set-up used fro lifting applications where a slow controlled descent of the load must be maintained

Double-acting cylinder set-up used in a push/pull application

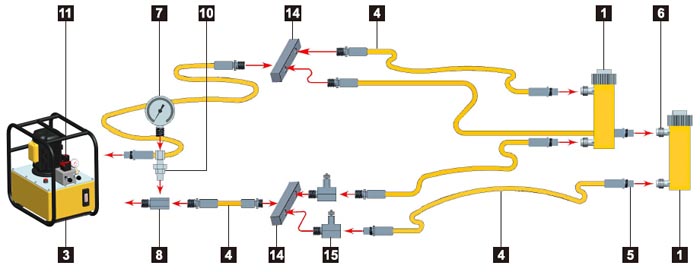

Two point lifting set-up using single-acting cylinders

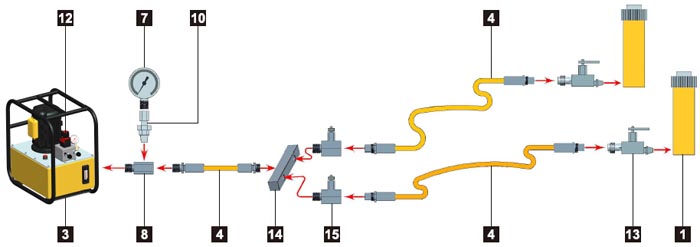

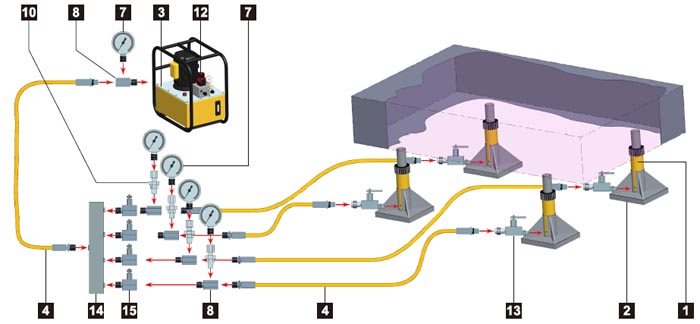

Four point lifting set-up, using single-acting cylinders and directional control valves

Notice:

1. CylinderApplies hydraulic force. 2. Cylinder Base Plate

For applications like lifting where additional cylinder stability is required. 3. Pump

Provides hydraulic flow. 4. Hose

Transport hydraulic fluid. 5. Male Coupler

For quick connection of the hose to system components. 6. Female Coupler

For quick connection of the hose end to system components 7. Gauge

To monitor pressure of the hydraulic circuit. 8. Gauge Adaptor

For quick and easy gauge installation. 9. Swivel Connector

Allows proper alignment of valves and/or gauge. Used when units being connected cannot be rotated. 10. Auto-Damper Valve V-10

Used to protect gauge from damage due to sudden pressure pulses in the system. Needs no adjustment and allows correct positioning of gauge, prior to tightening. 11. 4-way Directional Control Valve

Controls the direction of hydraulic fluid in a double-acting system. 12. 3-ways directional Control Valve

Controls the direction of hydraulic fluid in a single-acting system. 13. Safety Holding Valve

Controls load descent in lifting applications. 14. Manifold

Allows distribution of hydraulic fluid from one power source to several cylinders. 15. Needle Valve

Regulates the flow of hydraulic fluid to or from the cylinders.