This system uses hydraulic driving, pressure and displacement closed-loop automatic control mode to realize multi-point control, widely used in heavy load weighing, synchronous pushing, synchronous lifting, synchronous lowering, equal proportion lifting, attitude leveling and automatic voltage regulation etc.

Pump motor is controlled by frequency conversion speed regulator, depending on adjusting the frequency of the power supply to change the motor speed, which achieves the purpose of output flow can be regulated continuously. Accurate control on lifting speed to realize synchronous control of cylinders can be achieved by matching with proper electric control device and monitoring device. System Composition (Four points frequency conversion system as an example)

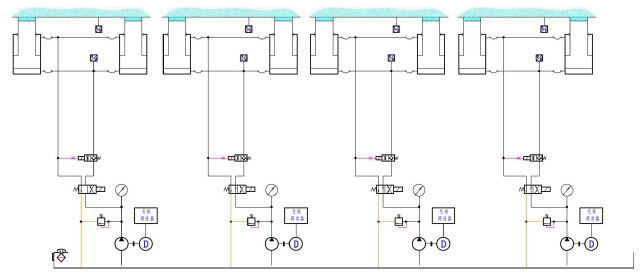

This system is composed of 4 pumps, 4 sets of frequency conversion speed control devices, 4 sets of control valve groups, electric control system and stroke sensors.

The bottom surface of the workpiece is not smooth, in order to ensure the same load of each hydraulic cylinder, before lifting the workpiece, firstly let the hydraulic cylinders contact with the workpiece evenly. Cylinders contact with the workpiece evenly as the benchmark of synchronous operating of hydraulic cylinders, for this purpose, this system has a fitting function. Start this function before synchronous lifting, hydraulic cylinders lifting at the same time, once the top of cylinder contact workpiece, this cylinder will stop lifting until all tops of cylinders contact with workpiece. Then the pressure of each cylinder is up to 5Mpa uniformly (Fitting pressure can be set in interface), at this time each cylinder stops lifting automatically and the position is regarded as the zero point of synchronization.

In this system, four sets of stroke monitoring devices are installed in the appropriate position of the control points. When the hydraulic cylinders lifting or lowering, the stroke sensor can measure the displacement of the hydraulic cylinders accurately in real time. A pressure sensor is also installed in the hydraulic cylinder oil inlet which can measure the load one the hydraulic cylinder. Also equipped with a balance valve, guarantee hydraulic cylinders in oil-taking speed control when lifting and lowering, keeping pressure reliably, ensure hydraulic cylinders will not fall freely and still can load bearing reliably in case of accidental power failure.

Hydraulic Scheme of Four Points Synchronous System

Electronic control system is the key to realize synchronous actions. It is based on the theory of closed-loop control system, the displacement signal of heavy moving as a controlled parameter, the pressure signal generated by heavy objects in force chamber of hydraulic cylinder is taken as a reference. Sensors collect these signals and transmit these signals to the controller. Controller accepts and processes these signals. Controllers operate these similar signals and compare with input tolerance, when a controlled point is found to have the possibility of exceeding tolerance, the controller sends a signal to drive the converter acting to close the hydraulic pump, which limits hydraulic cylinder lifting and lowering at this point. Similarly, when signal feedback indicates that the stop point has hysteresis, the controller sends a signal to drive the converter acting to start the hydraulic pump, which restores hydraulic cylinder lifting and lowering at this point. Through the precise control actions among these controlled points, synchronous control system achieves the purpose of synchronization in motion.

When the error of a controlled point can not be repaired by the controller, controller will alarm for system error and send signals to drive the converter acting at each controlled point to close the hydraulic pump, which make hydraulic cylinder at each controlled point stop working. Until this error is repaired and getworking demands from operator again, system will return to work.